Perma-Main™

The Perma-Lateral Trenchless Pipelining System is designed for 8″-24″ sewer pipe diameters.

Products Proudly Made In The U.S.A.

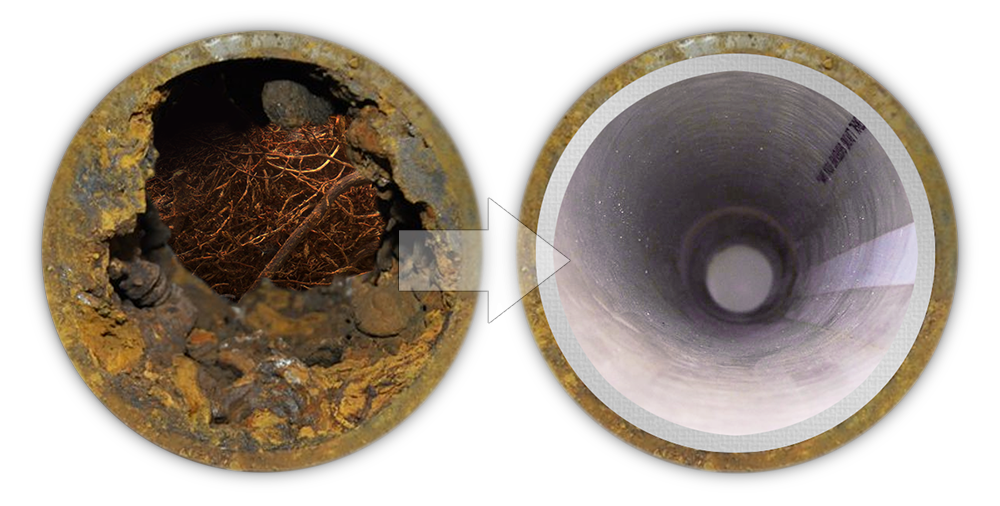

Save your sewer lines, save your slab, save your road, save your property. Reline your sewer today with Perma-Liner™

Perma-Lateral™

REHABILITATES PIPES FROM:

8″ TO 24″

IN DIAMETER

CONTINUOUS LENGTHS UP TO:

8” TO 24” LINING

600FT +

THIS NO-DIG TRENCHLESS SEWER REPAIR PROCESS SIMULTANEOUSLY REHABILITATES THE CONNECTION AND THE LATERAL SERVICE PIPE FOR UP TO 600 FEET IN LENGTH.

Continuous Lining Manhole To Manhole

Perma-Main™ Top Gun™ Cured-In-Place-Pipe (CIPP) Manhole to Manhole Inversion Rehabilitation System. The Perma-Main™ Top Gun™ lining system is designed for 8″ – 24″ Diameter Pipelines. The materials are air inverted through existing manholes and steam cured in as little as 1 ½ hours. The Perma-Main™ Top Gun materials can be installed safely, fast, and efficient. Installations average 300FT to 600FT in length. Transitions from 6″ – 8″ can be accomplished in a single installation. Materials are delivered prewet out, ready for installation. Installation equipment is compact and user friendly.

Highlights & Features

- Operates With Air Only, No Water

- Compact, Less Equipment & Traffic

- Quick Inversion, Under 10 Minutes

- Safe, Contractor Friendly

- Formulated Resin Allows For Longer Pot Life

- Compact Equipment Equals Less Space Required

- Air Inversion, No Water Or Large Boiler Inversion Trucks

- Steam Cure, Half The Time Of Hot Water Cure Systems

- Pre-Impregnated Liner Delivered Project Specific

Proudly Made In The U.S.A.

This patented sewer pipe repair system is ASTM F2561 Compliant.

Large Diameter Pipe Repair Solutions Made in the U.S.A.

END SEALS ELIMINATE EXPENSIVE GROUTING EQUIPMENT FOR YOUR CIPP LINERS

The #1 preventative maintenance tool to solve infiltration & inflow. Seal your collection system with a seamlessly molded seal – compatible with all cured-in-place-pipe systems

Air to invert

360 degree swelling gasket

Compatible with multiple types of cipp liners

Steam to cure

Significant surface area

Retaining rings

Technical Data:

HIGHLIGHTS

- Operates With Air Only, No Water

- Compact, Less Equipment & Traffic

- Quick Inversion, Under 10 Minutes

- Safe, Contractor Friendly

- Formulated Resin Allows For Longer Pot Life

- Compact Equipment Equals Less Space Required

- Air Inversion, No Water Or Large Boiler Inversion Trucks

- Steam Cure, Half The Time Of Hot Water Cure Systems

- Pre-Impregnated Liner Delivered Project Specific