ultraviolet inversion is here!

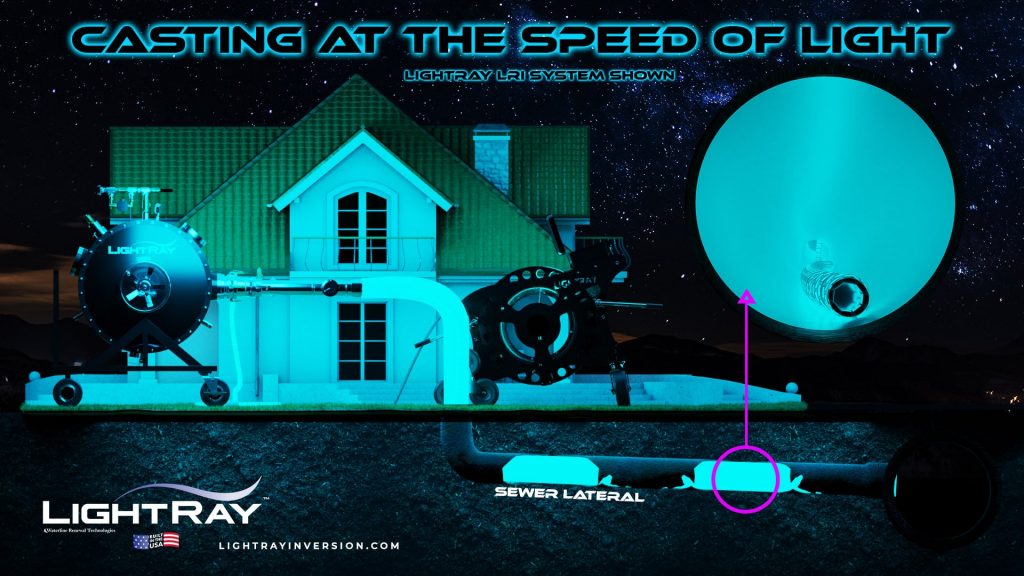

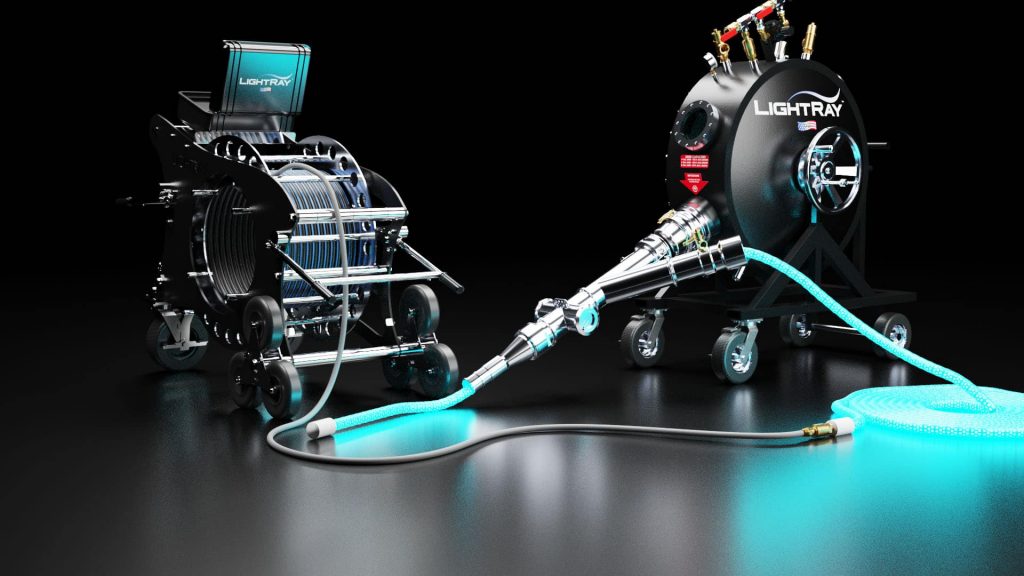

lightray lrI

The vision of LightRay is to provide next-generation UV technology to the CIPP industry using specially designed low voltage cold source LED UV pipe lights and higher strength pre-impregnated glass fiber pipe-liners, for the ZERODIG™ contracting industry involved in small diameter pipe infrastructure repairs.

lightray = Better than all the rest

LightRay’s state-of-the-art Cast-in-Place-Pipe technology ushers the Trenchless industry into the twenty-first century, offering new opportunities for plumbers and municipal contractors by significantly reducing time and resources, lowering risks and costs with much faster and higher quality results compared to the older traditional thermal heat or ambient curing processes.

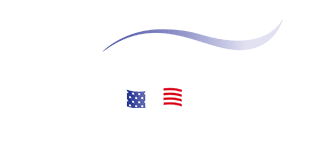

meet the all-new

lateral inversion system

The new LightRay LRI LED UV system is the most advanced cast in place UV pipe technology allowing the operator complete control of the casting process. Our patent-pending, state-of-the-art technology can significantly reduce your costs and risks when compared to traditional thermo-setting or ambient-cured CIPP liners, creating new opportunities for plumbers and municipal contractors.

get the latest uv technology in your toolbox

The new LightRay LRI system is the most advanced entrant to the UV cast inversion liner market. Our simple system allows the operator complete control over the process and very closely resembles traditional ambient cure inversion methods. The difference is that we can accomplish throughput of up to 6.3 feet per minute of casting with the proprietary double strand, cold LED light train, that requires no heat to cast the liner. The light train is offered in a standard length of 50 feet and only requires low-voltage to cast and is internally protected to accommodate bends in pipes up to 90 degrees.

cast 150ft

at 6.3 ft/minute

The 50 foot light train incorporates double strand, cold LED lights for industry leading cast times and does not rely on heat to cast the liner.

Ready to install without refrigeration

No more carrying resin materials in your truck or trailer and no need to measure and mix on site. LightRay liners arrive ready to install without any need for refrigeration. This greatly reduces the variability from mixing and preparing liners but also eliminates the requirement for extra equipment in the field allowing for rapid deployment of the system. The LRI system uses non-thermal UV casting resin that is temperature stable and only activated by UV light coupled with high-strength flexible fiberglass coated liners. No matter the temperature in the working environment, the casting times are consistent every time.